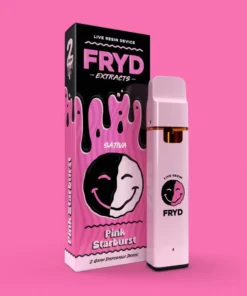

Fryd extraherar levande harts till salu

€20.00

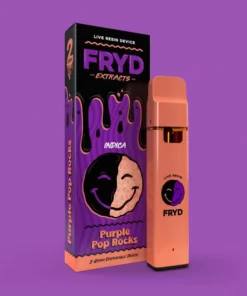

Fryd extraherar levande harts till salu

€20.00

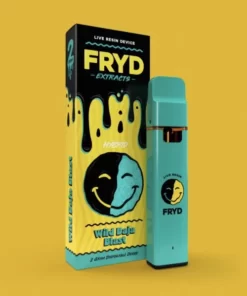

Fryd extraherar levande harts till salu

€20.00

Fryd extraherar levande harts till salu

€20.00

Fryd extraherar levande harts till salu

€20.00